Block Paving Leeds

Contact Paving Leeds for block paving driveways and pathways - many styles and layouts available

INCLUDE A PHOTO & MEASUREMENTS FOR A QUICK ESTIMATED BLOCK PAVING QUOTE

SEND ANYTIME 24/7

Paving Leeds block paving enquiry

Block Paving

Block Paving has been very popular since the 1980's initially for driveways and it provided a good quality robust alternative to tarmac and much more practical than gravel. At it's inception the choices for block paving were much less than they are today both in terms of colours, sizes and shapes. In terms of materials the same two account for the bulk of block paving namely cement and clay. However, most of the more modern colours and shapes will be made from cement as the manufacturing process of the raw materials makes it relatively easy to create new shades or colours.

Block paving is a little different in installation compared to the larger slabs as that the surface layer onto which the bricks or blocks are laid will be a sharp sand and screed mix which will take a little longer to set. The sand screed mix will be on top of a suitably compacted sub-base and then once all the blocks are in place brushing in kiln-dried sand into the gaps will stabilise the block paving.

As block paving uses much smaller blocks then the other paving slab alternatives, it is a very good option in you have a gently sloping garden as an alternative to excavating and installing retaining walls which will be required when fitting large pavers

Block Paving layers near me

If you are looking for block paving layers near me in Leeds of the day or night through our 'Send Enquiry' form

Block Paving Installers Leeds

Now that block paving has grown so much in popularity there a a number of block paving options. Firstly let's discuss the material which will either be concrete or clay blocks - or stone imports. Both traditional blocks provide robust surfaces although clay is somewhat tougher making it hard to cut which will add to installation costs. The advantages of cement as a materials will therefore be cost, although there will be a spread of these based on size, shape and colour however, they will be more prone to fading than clay, which will however, be much more limited in colour options. Clay is also a little more prone to to moss growth due to being slightly more permeable than concrete, which therefore provide better drainage. This difference also means that cement block paving is more resistant to spills and stains which is why it is a good choice for driveways. Regarding stone blocks, these could primarily be made up from granite or a sandstone quartz. They are typically reconstituted stone (or engineered stone) meaning that they have be formed using natural stone crushed and then bound together with a resin to form a block this allows them to be made uniformly and provide another material choice.

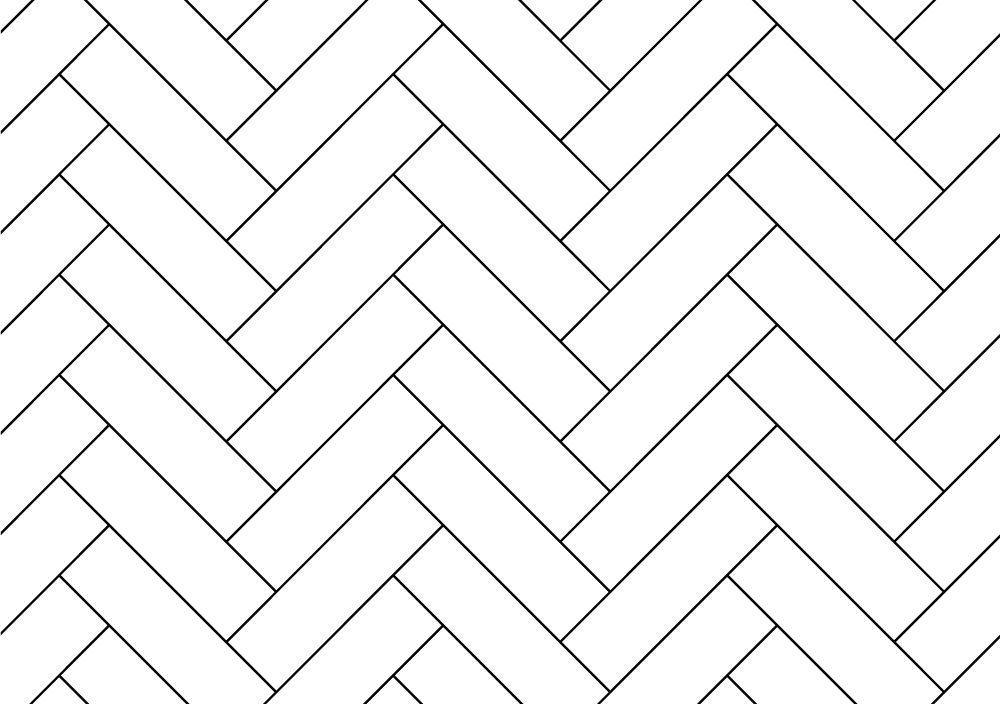

Block Paving Patterns

Block Paving Shapes

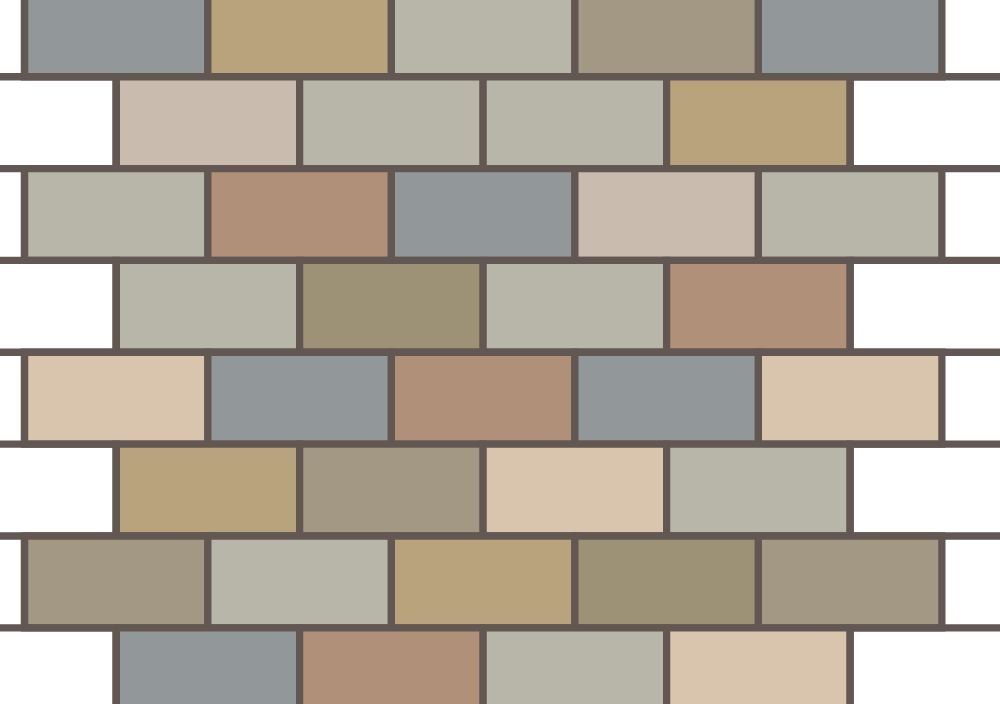

The amount of colour and shape options for cement block paving is huge however, the most popular are shades of red, blue/black and more recently grey. The beauty of block paving is that you can alternate two or more single colour bricks quite easily or opt for a style commonly referred to as brindle block, which is a single brick which has a blend of colours within it.

Clearly colour will be a personal choice but it is important to look at the existing surroundings and if going for a slightly bolder red or yellow option, using a darker block to edge or border your paving can help it blend into its surroundings a little better.

Regarding shapes, this too will come down to personal choice so as well as the standard rectangular or square block shapes such as S-blocks and W-blocks, hexagonal, axe head shaped. However, they are generally associated with commercial premises or public walkways such as town centres as they become more pedestrianised and they can be ordered in very large quantities in one go.

Block Paving Maintenance

One of the first maintenance task will be to add some additional jointing sand after the first few weeks after there has been some settlement of your block paving. For light cleaning the same approach can be applied to block paving as for large pavers - namely a brush with a still broom along with some water detergent mix. With block paving it is important to take preventative action regarding weeds so applying a weed killer after cleaning is well advised.

Whilst pressure washing is a good way to bring out engrained dirt from the bricks this can have a detrimental effect on the jointing between bricks. Utilising a pressure washer on a medium setting and angled at less than 30 degrees, spraying across joints will minimise jointing damage. Whilst it can be very tempting to use a pressure washer to blast our any weeds or moss from joints taking this approach will require joints to be repointed with jointing sand to prevent further and faster weed and moss growth.

Need help?